Maintenance

Our comprehensive Pitch Maintenance Programme is designed to maximise the performance, safety, and longevity of synthetic playing surfaces. Key elements of the service include:

Debris Clearance: All large and small debris is removed from the pitch surface.

Perimeter Treatment: Moss, algae, and weeds around the pitch are treated using safe and effective methods.

Inspection & Repair: Grass seams, joints, netting, and fencing are thoroughly inspected and repaired in line with client contract terms.

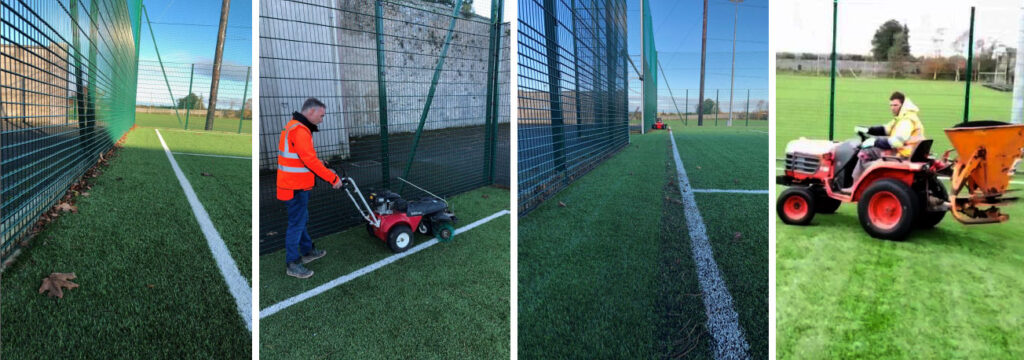

Surface Cleaning & Aeration: The pitch is cleaned and aerated using an oscillating rotary brush and a specialist vacuum system to remove fine debris like gum, gravel, and cigarette butts.

Infill Top-Up & Revitalisation: Infill levels are measured and replenished as needed. A mechanical tine brush is used to evenly distribute the new infill, restoring grip, bounce, and softness to the playing surface. Post-brushing measurements are taken to verify that infill levels meet performance requirements.

Reporting: A detailed maintenance report is provided to the client, including professional recommendations for ongoing care and any necessary follow-up actions to prolong the pitch’s lifespan and maintain peak performance.

Results of Cleaning & De-compaction

Regular cleaning and de-compaction have proven to:

- Improve drainage

- Extend the overall life of the pitch

- Enhance player comfort and reduce injury risk

- Restore ball bounce and surface grip

All large pitch debris is cleared and all netting and fencing checked for faults.

A depth gauge is used to record infill levels. From this we are able to determine the required infill top up. Grass seams (joints) are also checked for any potential faults.

The surface is cleaned aerated and brushed using an oscillating rotatory brush and specialist pitch vacuum to collect any smaller debris. New rubber may be introduced back into the pitch to revive grip, ball bounce and softness bringing back some of that new pitch feel.

Results of Cleaning and de-Compaction

Tips for Proper Pitch Maintenance

- Moss, Algae & Weed Control: Early intervention with professional chemical treatments is key. Always consult with the pitch installer for the best approach.

- Maintenance Logbook: We strongly recommend maintaining a logbook to track all maintenance activities and pitch usage. This supports warranty claims and helps schedule routine servicing.

- Deep Cleaning: When compaction or debris accumulation becomes significant, we deploy specialised machinery that removes, cleans, and redistributes infill as required.

- Infill Levelling: Routine brushing—every 30 hours of play—is essential to maintain even infill distribution and upright grass fibres.

Additional Maintenance Tools

To support our clients, we also offer boot cleaners for pitch entrances, helping to reduce the amount of dirt and debris brought onto the surface.

We also supply drag brushes to help maintain consistent infill levels and upright fibres through regular use.

Contact us today for a quote on pitch maintenance equipment, including boot cleaners and drag brushes.